On October 22, 2025, the 9th China (Foshan) International Hydrogen Energy and Fuel Cell Technology & Products Exhibition (CHFE2025) officially kicked off at Nanhai Qiaoshan Cultural Center. As an annual grand event in the hydrogen energy industry, this exhibition gathered over 150 enterprises worldwide and more than 10,000 professional visitors. EVE Hydrogen Energy participated with its full range of AEM hydrogen production equipment. Among them, the previously unveiled MW-class AEM electrolyzer became the focus of the exhibition due to the key breakthrough of "successful completion of full-stack testing". Additionally, Li Junwei, Product Manager of EVE Hydrogen Energy, delivered a keynote speech at the concurrent HySpace Innovation Technology Forum, providing an in-depth decoding of the industrialization advancement path of this technology from R&D to validation.

| Forum Insight: Full-Chain Breakthroughs of AEM Technology from Materials to Validation

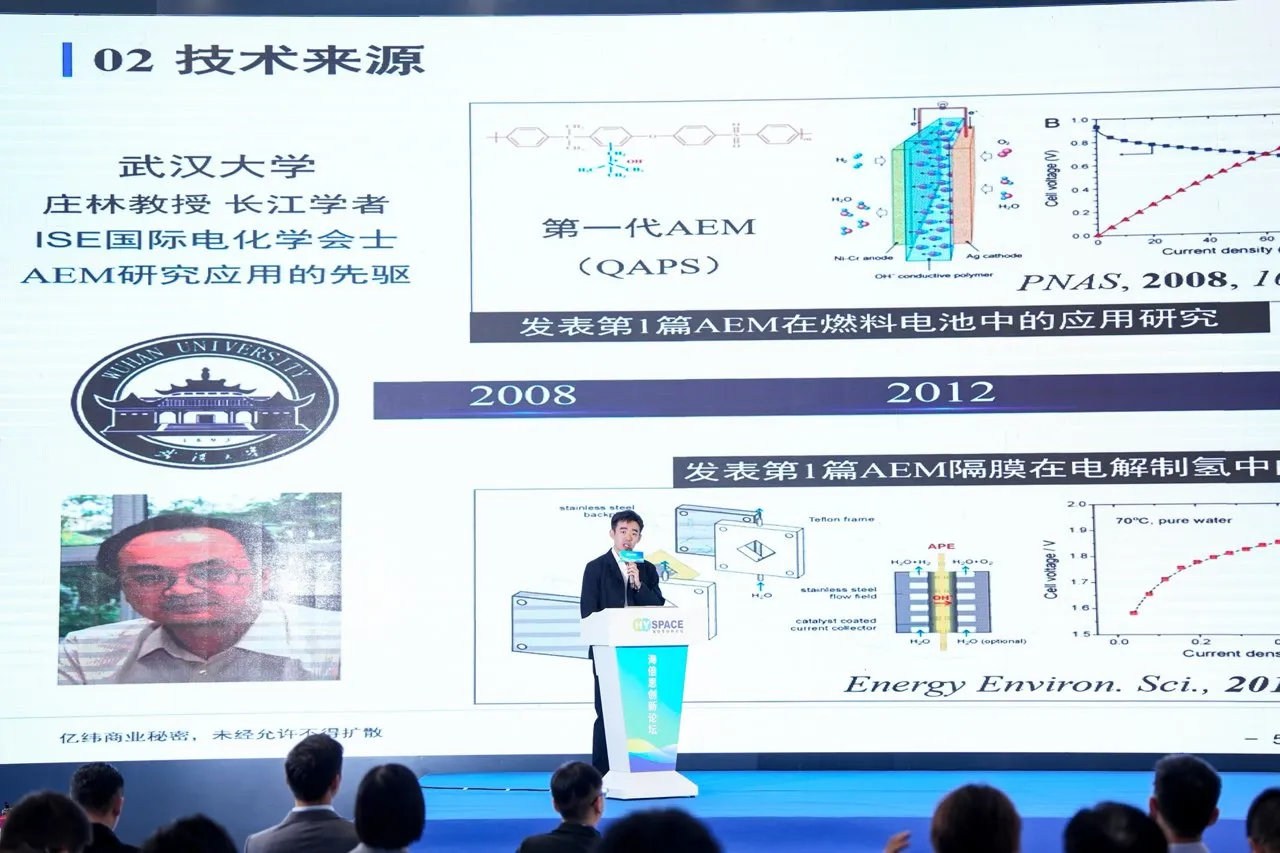

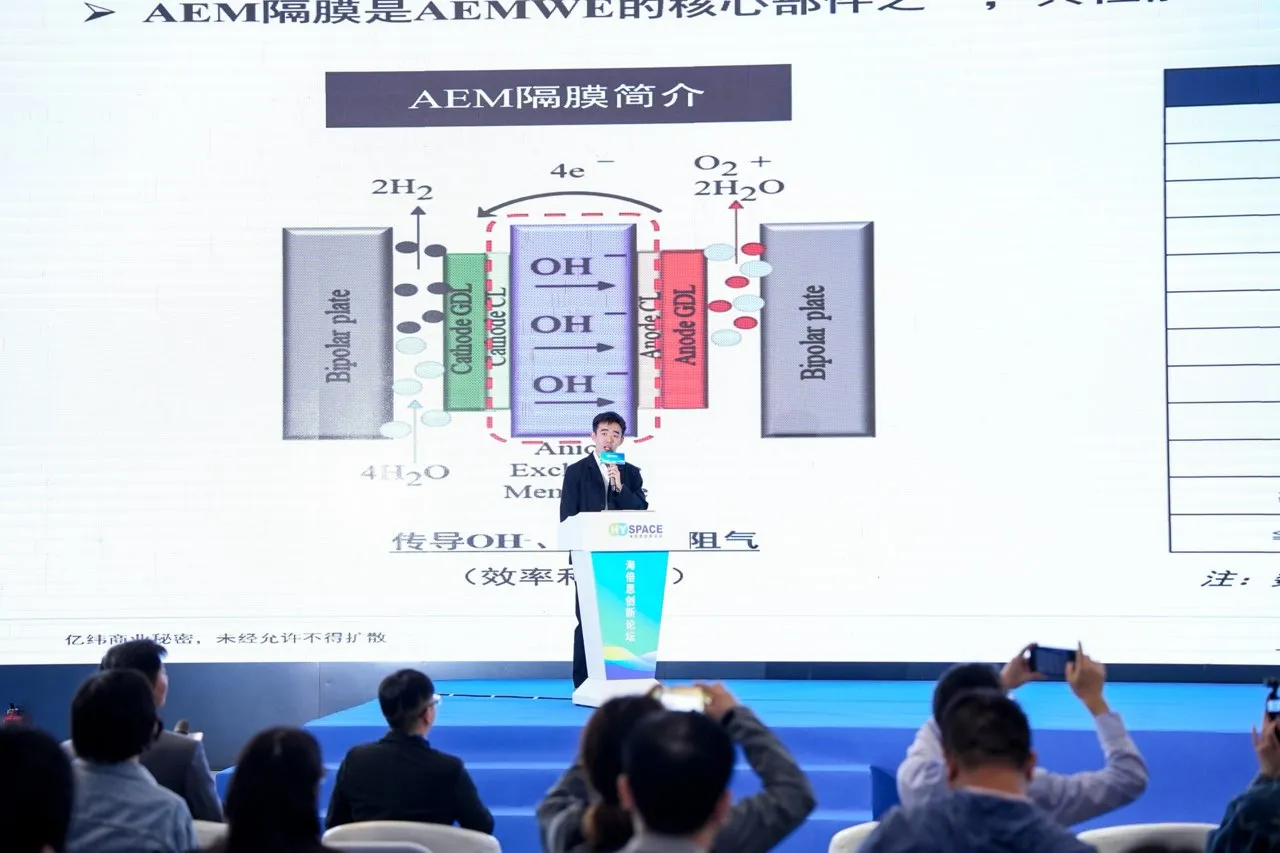

At the core session of the conference — the HySpace Innovation Technology Forum, Li Junwei, Product Manager of EVE Hydrogen Energy, delivered a speech titled "EVE Hydrogen Energy: AEM Technology Advancement and Industrialization Practice", systematically elaborating on the company's full-chain layout in the hydrogen energy field. He introduced that since EVE Hydrogen Energy entered the hydrogen energy sector in 2018, it has built a complete technical system covering "basic material R&D — system integration design — scenario-based validation", with core support from the iterative upgrading of AEM membrane technology derived from the team of Professor Zhuang Lin from Wuhan University.

When talking about technical achievements, Li Junwei highlighted key data: Its W-75 membrane material has operated for 10,000 hours with a voltage decay of <10μV/h, reaching an advanced industry level in stability; the new-generation W-75T AEM membrane material achieves a cell voltage as low as 1.66V at a current density of 1A/cm², demonstrating excellent electrochemical performance; the modular hydrogen production system has served over 30 customers at home and abroad, obtained CE certification, and operated under actual working conditions such as frequent start-stop for more than 10 months at customer sites; the 100kW centralized system has operated stably for over 4,000 hours at the Hubei Jinquan Project. The core highlight of this exhibition — the MW-class AEM electrolyzer, has officially completed full-stack testing, marking a critical step toward its commercialization, which highly aligns with the conference theme "Innovation Leads • Hydrogen Links the Globe".

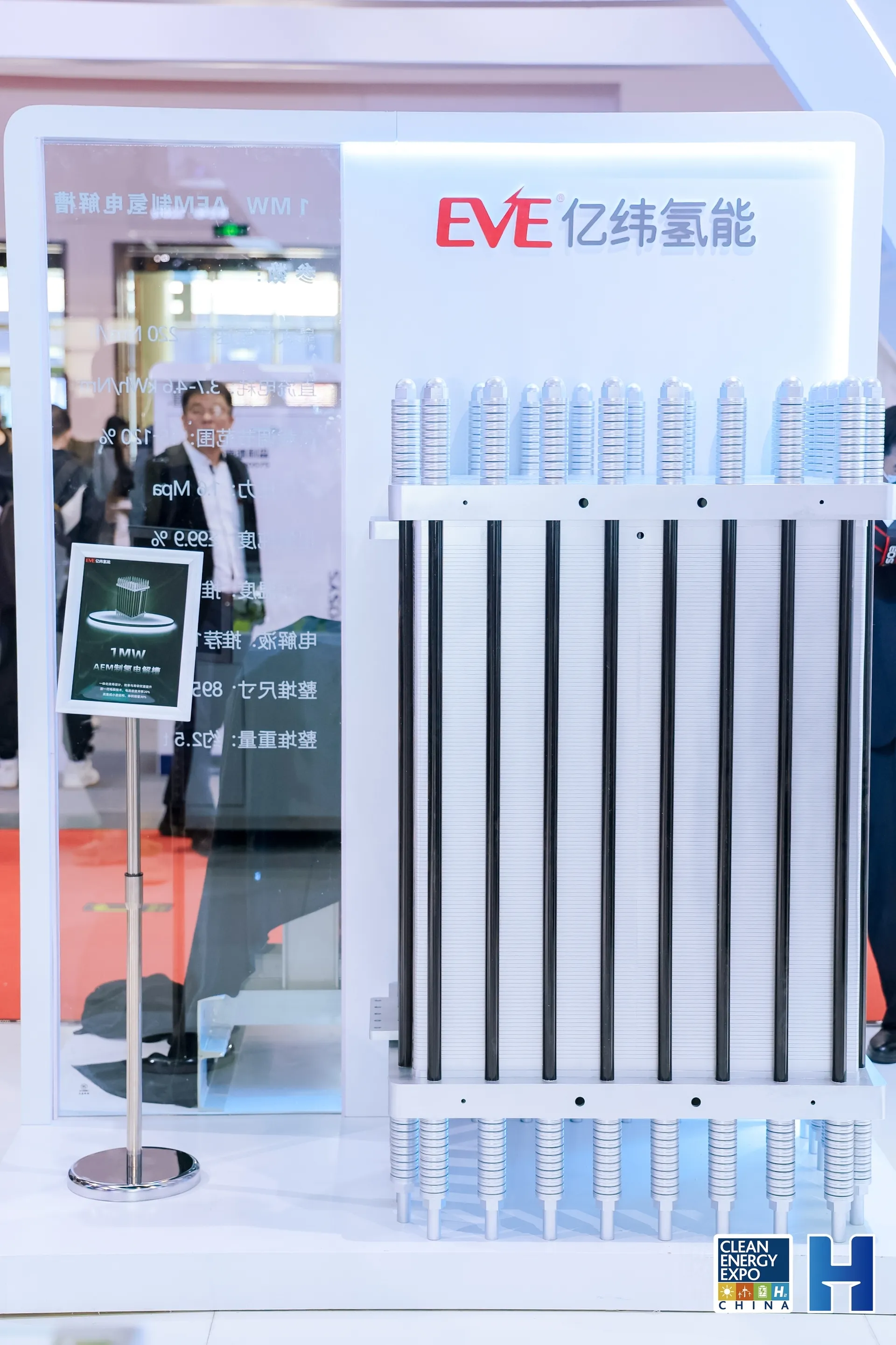

| Exhibition Highlight: Full-Stack Test Data Revealed, Defining New Standards for MW-Class Safety and Efficiency

At EVE Hydrogen Energy's booth, the MW-class AEM electrolyzer that completed full-stack testing became the core attraction for professional visitors. The on-site released test data demonstrated strong technical capabilities: Under a working pressure of 1.6 MPa, even at a low load of 15%, the hydrogen content in oxygen remains ≤1.5%, far exceeding the industry safety threshold. It can accurately adapt to the fluctuating output of wind and solar power sources, perfectly meeting the core requirements for green hydrogen production in large-scale projects such as the Guangzhou-Zhanjiang Hydrogen Expressway. Meanwhile, the electrolyzer has achieved structural innovation, with a rated hydrogen production capacity of 220Nm³/h, an active area ratio increased by over 50%, and a unit thickness reduced by 1/3. While maintaining a low power consumption of 4.3kWh/Nm³, it significantly reduces equipment volume and land occupation costs.

Also on display were the industrially validated 100kW-class centralized hydrogen production system and modular hydrogen production system: The centralized system covers a hydrogen production scale of 20-200Nm³/h, with a load adjustment range of 20%-120%, and can cold-start to rated conditions within 20 minutes; the modular system produces 3Nm³/h of hydrogen per cabinet, which can be stacked to expand to 20Nm³/h. After 4,500 hours of testing, its power consumption remains ≤4.3kWh/Nm³, with hydrogen purity reaching 99.999%, suitable for diverse scenarios such as scientific research and small-scale industry.

| Focus on Implementation: Accelerating MW-Class Project Commercialization with Full-Chain Strength

"The completion of full-stack testing is a core milestone for the MW-class AEM electrolyzer to move from technical prototype to industrial application," emphasized Li Junwei. Leveraging 80 core patents, an annual AEM membrane production capacity of over 10,000 square meters, and in-depth industry-academia-research collaboration with universities, EVE Hydrogen Energy has achieved full independent control from membrane materials to system integration. Currently, its products have been validated in scenarios such as industrial metallurgy and off-grid hydrogen production from wind and solar energy. The next step is to promote the implementation of MW-class AEM hydrogen production demonstration projects, providing solutions for scenarios such as chemical industry, metallurgy, and hydrogen production & refueling stations, and facilitating the transformation of the hydrogen energy industry from "pilot exploration" to "orderly breakthrough".

From technical R&D to full-stack validation, from scenario adaptation to large-scale promotion, EVE Hydrogen Energy is continuously advancing AEM technology, injecting "Chinese momentum" into the global green hydrogen industrialization.