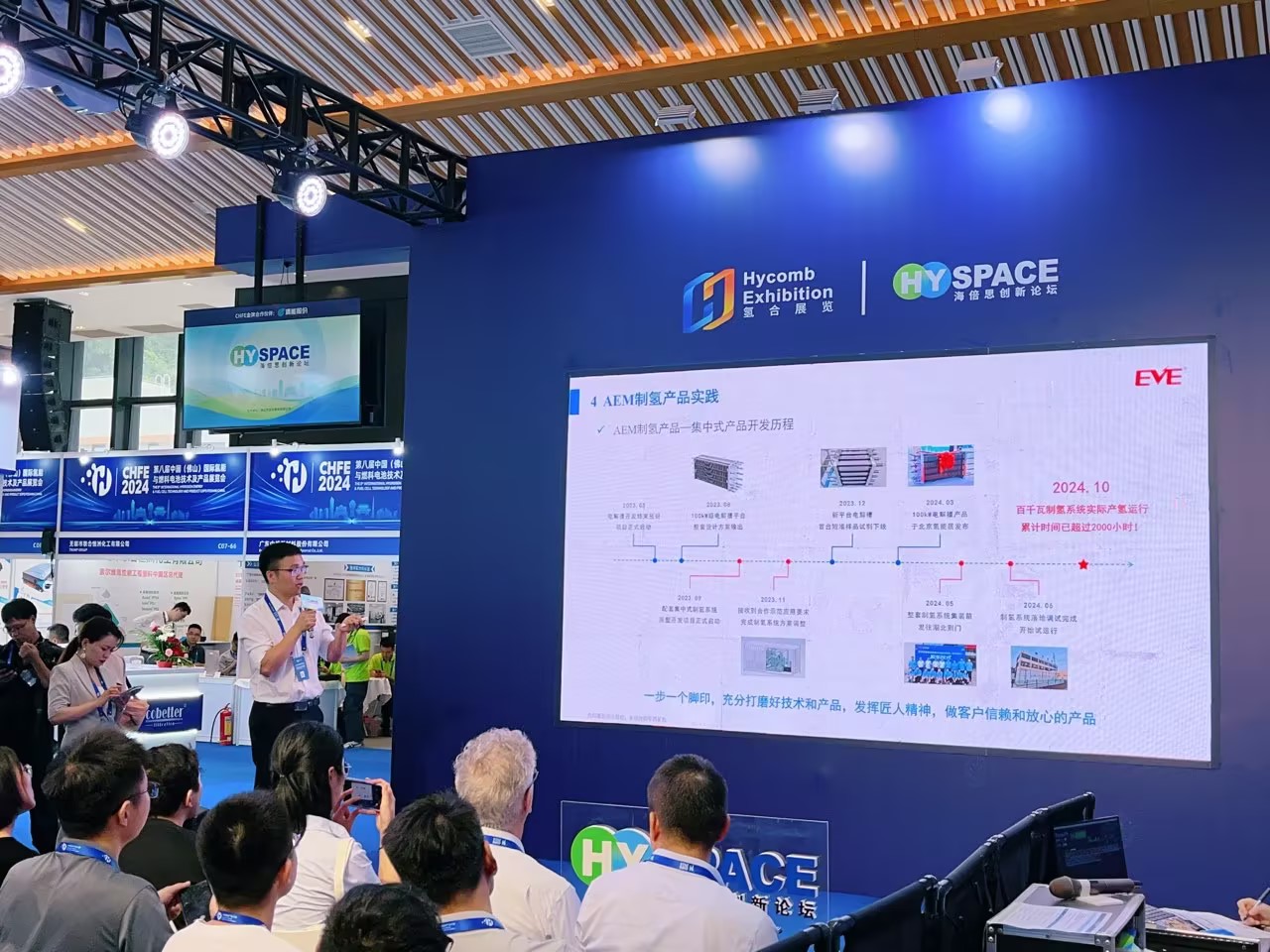

On October 18, the 2024 China (Foshan) International Hydrogen Energy and Fuel Cell Technology Exhibition grandly opened at the Qiaoshan Cultural Center in Nanhai, Foshan. At the Hyspace Innovation Forum, EVE Hydrogen Energy's AEM centralized hydrogen production system was officially released, and it was announced that the company's first domestic 100-kilowatt-level AEM hydrogen production system had been stably operating for more than 2,000 hours.

At the conference, Su Xiangdong, Director of the Basic Platform Technology Center of EVE Hydrogen Energy, gave a keynote report entitled "Industrialization Practice of AEM Water Electrolysis Hydrogen Production Technology". He stated that the existing hydrogen production methods of hydrogen production can be divided into distributed hydrogen production and centralized hydrogen production according to the hydrogen production scale and equipment volume. The centralized hydrogen production system refers to the mode of hydrogen production in a single, large facility. This design is more suitable for large-scale hydrogen consumption scenarios. For this reason, EVE Hydrogen Energy's 100-kilowatt-level centralized hydrogen production system (CSM series) came into being. Now it has two platforms, CSM20 and CSM100. Based on these two platforms, customized configurations can be made as needed, covering application scenarios of 5-500 standard cubic meters.

At the conference, Su Xiangdong, Director of the Basic Platform Technology Center of EVE Hydrogen Energy, gave a keynote report entitled "Industrialization Practice of AEM Water Electrolysis Hydrogen Production Technology". He stated that the existing hydrogen production methods of hydrogen production can be divided into distributed hydrogen production and centralized hydrogen production according to the hydrogen production scale and equipment volume. The centralized hydrogen production system refers to the mode of hydrogen production in a single, large facility. This design is more suitable for large-scale hydrogen consumption scenarios. For this reason, EVE Hydrogen Energy's 100-kilowatt-level centralized hydrogen production system (CSM series) came into being. Now it has two platforms, CSM20 and CSM100. Based on these two platforms, customized configurations can be made as needed, covering application scenarios of 5-500 standard cubic meters.

The CSM series products have the following outstanding advantages. In terms of system energy consumption, the DC power consumption under rated conditions is as low as 4.3 kWh/Nm³, and the comprehensive energy efficiency of the equipment is higher; In terms of dynamic response, it has a rapid cold start and can reach the rated operating condition within 20 minutes, which can quickly respond to fluctuating power and improve the utilization rate of renewable energy power; in terms of load range, it can flexibly respond to various fluctuations and meet users' more detailed usage needs; In terms of floor area, the overall size is only half that of an alkaline tank system of the same standard cubic meter level; in terms of safety performance, it uses explosion-proof parts as a whole and is equipped with all-round safety monitoring. It can be started, stopped and vented emergently with one click.

The CSM series products have the following outstanding advantages. In terms of system energy consumption, the DC power consumption under rated conditions is as low as 4.3 kWh/Nm³, and the comprehensive energy efficiency of the equipment is higher; In terms of dynamic response, it has a rapid cold start and can reach the rated operating condition within 20 minutes, which can quickly respond to fluctuating power and improve the utilization rate of renewable energy power; in terms of load range, it can flexibly respond to various fluctuations and meet users' more detailed usage needs; In terms of floor area, the overall size is only half that of an alkaline tank system of the same standard cubic meter level; in terms of safety performance, it uses explosion-proof parts as a whole and is equipped with all-round safety monitoring. It can be started, stopped and vented emergently with one click.

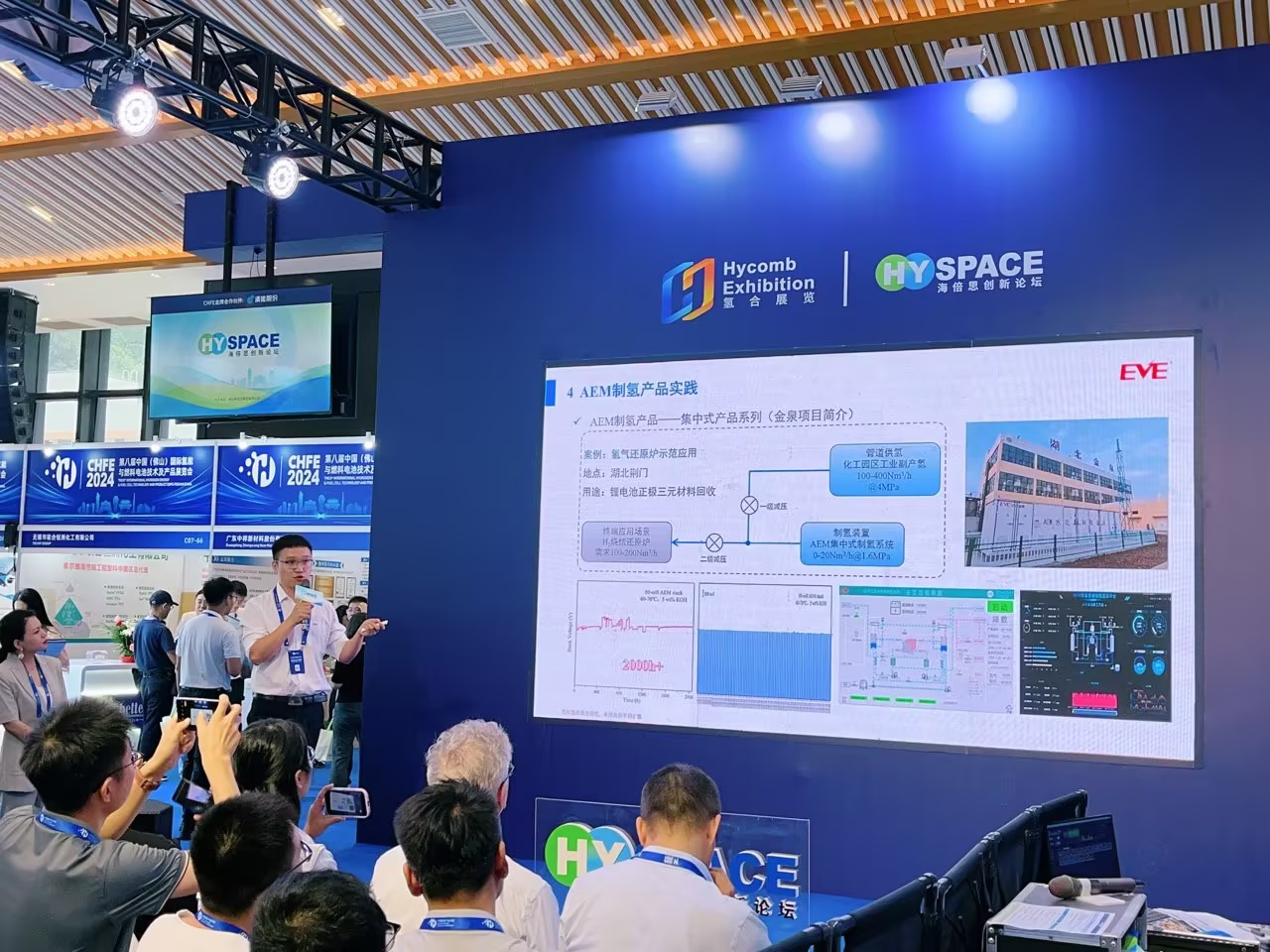

In terms of project application, EVE Hydrogen Energy's first domestic 100-kilowatt-level AEM hydrogen production system was shipped to Hubei on May 11, 2024. As of October 2024, this system has been stably operating for more than 2,000 hours. During some periods, hydrogen production is carried out at 120% load. Except for on-site power maintenance and power regulation and other situations, this system remains in uninterrupted operation 24 hours a day.

In terms of project application, EVE Hydrogen Energy's first domestic 100-kilowatt-level AEM hydrogen production system was shipped to Hubei on May 11, 2024. As of October 2024, this system has been stably operating for more than 2,000 hours. During some periods, hydrogen production is carried out at 120% load. Except for on-site power maintenance and power regulation and other situations, this system remains in uninterrupted operation 24 hours a day.

It is reported that this 100-kilowatt-level AEM hydrogen production system has been strictly controlled and verified throughout the entire process from electrolyzer design and manufacturing to system integration and final assembly, so as to ensure that each unit and module are highly unified and matched in performance parameters and ensure the overall operating efficiency and stability of the system.

It is reported that this 100-kilowatt-level AEM hydrogen production system has been strictly controlled and verified throughout the entire process from electrolyzer design and manufacturing to system integration and final assembly, so as to ensure that each unit and module are highly unified and matched in performance parameters and ensure the overall operating efficiency and stability of the system.

As the first (set) single-tank 100-kilowatt-level AEM hydrogen production system at home and abroad, this is not only a major demonstration of AEM water electrolysis hydrogen production technology, but also fully demonstrates the mature application of non-noble metal catalysts and high-strength anion exchange membranes in commercialization, providing another mature and reliable solution for the selection of hydrogen production technology routes from water electrolysis.

Looking to the future, the AEM centralized hydrogen production system with advantages such as low energy consumption, fast response, wide load and small size will enter the market one after another, providing one-stop, standardized, and all-weather AEM hydrogen production system solutions for customers with hydrogen demand in scenarios such as chemical production, metallurgical processing, green power coupling, grid-forming power generation, and hydrogen production and refueling stations, witnessing the miracle of China's green energy development in the world's energy transformation.

Looking to the future, the AEM centralized hydrogen production system with advantages such as low energy consumption, fast response, wide load and small size will enter the market one after another, providing one-stop, standardized, and all-weather AEM hydrogen production system solutions for customers with hydrogen demand in scenarios such as chemical production, metallurgical processing, green power coupling, grid-forming power generation, and hydrogen production and refueling stations, witnessing the miracle of China's green energy development in the world's energy transformation.